CREWpoint Contractors recognizes and understands the demands placed on manufacturing facilities and their operations.

The constant demand to increase efficiencies and production is stressful enough without the distraction of a capital project to manage. Our goal is to reduce stress by allowing our customers to focus on their core business. We appreciate the fact that trust must be earned and we will provide the highest level of service to earn yours.

- Extensive and Thorough Planning Processes

- Constant Communication between CREWS and Leadership

- Safety Awareness

- Internal and External Teamwork

- Quality Craftsmanship

- Dedicated CREWS

- Transparency and Honesty

At CREWpoint contractors, we employee Certified Welders and all employees have their OSHA 30 Certification.

Let us show you what makes us different.

Contact us to learn why CREWpoint Contractors is your best choice when in need of a crew.

Request a free quote.

CREWpoint offers turnkey solutions to maximize underutilized space, including open air space, in the form of plant floor reconfigurations and/or floating mezzanines. Below grade pallet dispensers and overhead accumulation conveyors are a couple of solutions that CREWpoint has installed to help customers maximize space utilization.

CREWpoint Contractors offers Project Management Services for a variety of construction jobs. We recognize that time is a luxury our customers do not have. Most large capital projects in Manufacturing facilities have multiple phases and the completion of these phases are all impacted by one another, therefore, it is vital that scheduling is well planned and coordinated from start to finish. CREWpoint Project Managers have all the tools needed to manage a project correctly. Safety awareness, communication, coordination, execution, commonsense and motivation are practiced daily by our CREWs and our leadership.

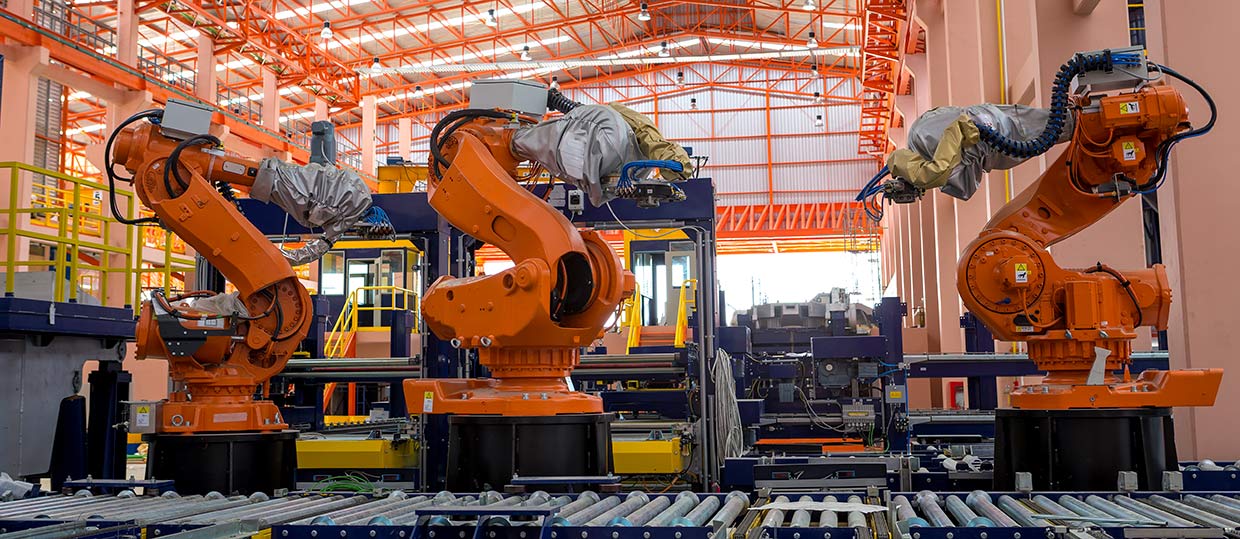

CREWpoint is your solution for the rigging and assembly of robotic equipment. Alignment, anchoring and grout will be done with the highest level of precision and workmanship. CREWpoint can also install or upgrade the necessary utilities for your new robotic cell. Foundation modifications may be required and CREWpoint Contractors has the CREW for that too!

With the proper PPE and equipment, CREWpoint can successfully complete your demolition needs. Salvation and segregation of recyclable materials will be practiced to help offset the removal cost of your obsolete equipment.

Most conveying systems can continue to be utilized upon the arrival of new process equipment on the production floor. CREWpoint wants to help our customers modify and reconfigure existing material handling equipment. Elevation changes and transitions can all be fabricated onsite.

Your plant is unique in many ways; we have yet to work in a factory that was identical to another. It is imperative that we provide a high caliber of steel fabrication to our customers. Custom solutions are fabricated in the field to ensure all requirements are met. Access platforms, safety ladders, guard rails, fencing and transitions are a few examples of this.

Our riggers have the experience and equipment to safely move machinery within your facility or to another facility. We have invested in our riggers to help protect our customers’ equipment investments.

Stainless Steel, Carbon Steel, Copper, Aluminum and Poly, Welded, Threaded, Glued, and Coupled Pipe- CREWpoint pipe fitters can install your piping with professionalism and consistency, and also the foresight to allow for future expansion. Flow, volume, and maintenance will all be on the forefront when designing and installing your piping solution.

CREWpoint helps resolve moisture, scaling pipe, low volume and unbalanced systems issues. CREWpoint will increase volume on the production floor, install zero loss drains, new compressors, dryers, filters and receivers. Future expansion, maintenance and uninterrupted production are always considered when designing a new system or upgrading an existing system.

CREWpoint Millwrights read blueprints, understand hydraulics, mill maintenance, industrial math and welding. Their skills, both physically and mentally, allow them to successfully practice problem solving, keen attention to detail, analytical thinking and innovation every day. A Millwright’s most important tools are their mind and their body. A healthy Millwright is a successful Millwright.

Maintenance:

CREWpoint recognizes the constant wear and tear in warehouses and plants can quickly result in safety hazards; we are ready to help eliminate such hazards and improve the overall appearance of your facility. Preventive measures taken on floor and joint repairs are necessary to increase the life span of your material handling equipment and allow for safe foot traffic. Planetary grinders, densifiers and polish will prevent concrete dusting to give your facility the professional look that is sure to impress your customers, keep your employees safe and minimize wear and tear on equipment.

Revitalization:

As America has turned its interest to the revitalization of urban city centers, many old warehouses and manufacturing facilities have suddenly become very valuable but are in need of an “Extreme Makeover.” CREWpoint Contractors has the necessary skills to complete your Warehouse and Facility Revitalization. Whether you need to reconfigure an aging structure into a modern state-of-the-art facility or completely repurpose it for another use, CREWpoint Contractors is your solution.

Download our flyer to view our full list of services.

CREWpoint Solutions

Our CREWpoint Solution product is especially attractive to large corporations with multiple locations throughout the United States who have reoccurring maintenance needs at their various facilities. We work closely with each facility to craft a custom maintenance plan and schedule, and then dedicate a “CREW” who, through repetition, create efficiencies and scale those efficiencies throughout your various facilities.

Contact us the learn more about our CREWpoint Solution.